有机硅耐热面漆 Silicone heat resistant finish的价格

1.有机硅耐热面漆 Silicone heat resistant finishPrice calculation method correctly

DreamTherm 400 topcoat:有机硅耐热面漆耐高温400度,该产品是由特种有机硅耐热树脂、耐热颜料、填料、助剂及溶剂组成。耐热性能优异;附着力强,机械性能好。 The silicone heat-resistant topcoat has a high temperature resistance of 400 degrees. This product is composed of special silicone heat-resistant resin, heat-resistant pigments, fillers, additives, and solvents. Excellent heat resistance; Strong adhesion and good mechanical properties.

In the purchase ofDreamTherm 400 topcoat the need to consider the following 6 aspects, is the correct calculation of the true price of paint.

1、 Volume solid portion of 有机硅耐热面漆 Silicone heat resistant finish

有机硅耐热面漆 Silicone heat resistant finish Volume volume of paint (volume solids),有机硅耐热面漆 Silicone heat resistant finishNon-volatile components and liquid $ The volume ratio of有机硅耐热面漆 Silicone heat resistant finish。This is a very important concept, the liquid $ After volatilization of the agent in 有机硅耐热面漆 Silicone heat resistant finish,the really left in the surface of the coating into the paint film is $ Non-volatile fraction in 有机硅耐热面漆 Silicone heat resistant finish namely,the solid fraction.

Dry film thickness (um) = wet film thickness (um) volume solid part

Example: PaintDreamTherm 400 topcoatProduct,the thickness of wet film is 100um and the thickness of dry film is 80um, calculating the volume solid points: volume solid content = dry film thickness / wet film thickness / 100=80%

The coating product Volume solids of DreamTherm 400 topcoat are divided into 80%.

2, Dry film thickness and wet film thickness

The thickness of the dry film is usually specified in the coating contract. The determination of the wet film thickness can help to determine the thickness of the dry film, and the construction of the thick coating layer can reach the specified dry film thickness. The determination of the wet film is conducive to timely find the difference in the thickness of each construction coating, in order to correct.

Known as the specified thickness of the dry film, consult the volume and solid content of the relevant products, calculate the corresponding wet film thickness, can be calculated according to the following formula.

Wet film thickness (um) = dry film thickness (um) / volume solid part

example:DreamTherm 400 topcoatVolume solid content is 80%, the dry film thickness reaches 100 microns, the calculation to DreamTherm 400 topcoatConstruction wet film thickness is how much to meet the requirements. Wet film thickness = dry film thickness / volume solid fraction =100 / 80%=125um.

3. Diluted wet film thickness

In the actual construction,the DreamTherm 400 topcoatDiluents are often added to the paint. The use of diluents increases the total volume, but does not increase the bulk solid content.for example,DreamTherm 400 topcoat Add 25% diluent to dilute the coating, only it is necessary to add 25% to the formula, calculate the thickness of the diluted coating wet film, according to the following formula:

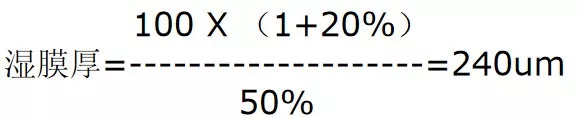

Wet film thickness = [Dry film thickness (1 +% diluent)] /% solid volume/strong>

example:DreamTherm 400 topcoat50% of 50% paint, 20% dilution, to construct 100um thickness dry film. In order to ensure the specified dry film thickness, what should be the wet film thickness for the construction of the paint?

4. Theoretical coating rate

For the owner and the contractor is the key factor to calculate the cost and coating dosage, the theoretical coating rate refers to the coating construction on a smooth surface without loss, every 1L of the area can be coated M2, the unit is M2 / L. By this definition, we can obtain the following formula for calculating the coating rate of liquid paint at any given dry film thickness (expressed in square 2 / liter):

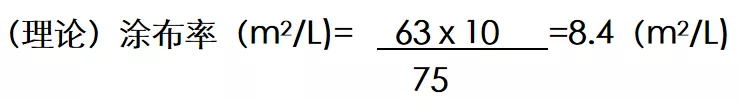

(Theoretical) coating rate (m2 / l) = volume solid part 10 / dry film thickness (um)

For example, the solid content of inorganic zinc rich primer is 63%, the dry film thickness is 75um, and the theoretical coating rate is calculated:

5. Actual coating rate

The actual coating rate is the percentage of loss minus the theoretical coating rate. The calculation formula is as follows:

Actual coating rate = theoretical coating rate (1-loss%)

If the theoretical coating rate has been calculated and the loss percentage of the coating can be estimated, such as the loss of 40%, then the theoretical coating rate of the previous inorganic zinc rich primer is 75 microns:

Actual coating rate=Theoretical coating rate(1-40%)=8.4(1-40%)=5.04m2/L

In fact, the loss percentage is uncertain, because the actual construction is affected by a variety of factors, the construction methods, the technology of the work, the shape of the coating, the roughness of the surface, the working environment and the distribution degree of the film paint.

6. the actual amount of paint

The actual amount of coating is obtained on the basis of the actual coating rate and can be calculated according to the following formula:

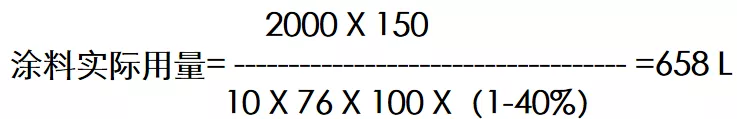

Actual amount of coating = (area dry film thickness) / 10 volume solid content 100 (1-loss%)

In the above formula, (1-loss%) is the loss coefficient.

Example: there is 2000M2 inside a storage tank, 2 courses of phenolic epoxy coating with a solid content of 76%, each 150 microns, the estimated loss of 40%, calculate how much L of phenolic epoxy coating should be used.

Then 2 coatings to total 6582=1316L

7.paint price calculation

A: Unit price per square meter

In the coating project quotation, paint manufacturers often use different paint products, or even if the same paint and different volume content of the products to quote, and the price of the quotation is different. Is it possible to say that the low price is the low cost? As it turns out, even if the unit price of products with high volume content is high, the unit price per square meter is often lower than those with low volume content.

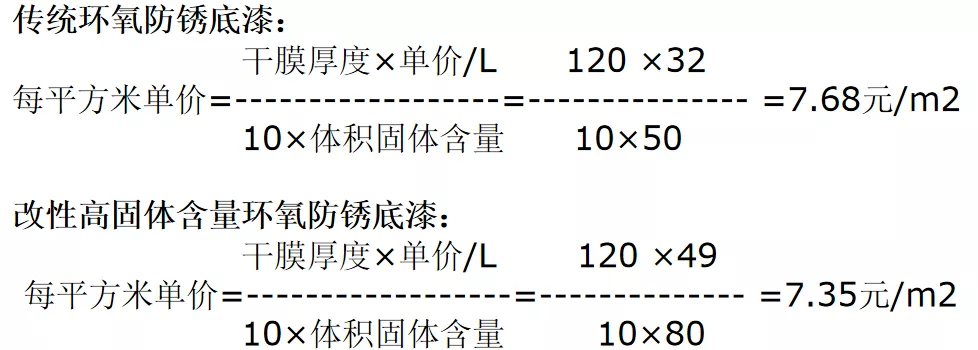

Unit price per square meter = (dry film thickness unit price / L) / 10 volume solid content

Example: a piece of structure, require construction dry film thickness of 120 micron epoxy primer, traditional epoxy primer solid content is 50%, if the unit price is 32 yuan / L, high solid content modified epoxy primer solid content is 80%, if the unit price is 49 yuan / L, it can be seen that the use of high solid content of modified epoxy primer, lower unit price per square meter.

B: The price conversion of liter and kg

Foreign coating companies in the coating formula design and technical data calculation and packaging specifications, all use the concept of L, domestic companies often with KG to carry out technical data calculation and packaging, the introduction of the concept of quality can be convenient calculation, the density of related data products can be obtained from the manufacturer's data manual.

Price per liter / density = price per kg

Example: an epoxy deiron intermediate paint has a density of 1.8 KG/L and the price of 48.8 yuan / L, then the price of the epoxy deiron intermediate paint per kilogram is 48.8÷1.8=27.11 yuan / KG

Since the density of coatings is usually higher than 1.0 KG/L, unless the dilution of the solvent is sometimes lower than 1.0 KG/L, the price per L looks larger than the unit price per KG.

2. Welcome to order theDreamTherm 400 topcoat

We expect that in the future development process, products and services will be recognized by everyone, at the same time, establish a good Corporate Culture and social responsibility, create excellent value for employees and customers, for the society and environment. In the future, we will always stay true to our original aspiration, forge ahead, continue to focus on the field of industrial anticorrosion, and strive to become a "trustworthy partner" in the eyes of customers. Protect your assets and enhance the value of your products through our professional and diversified services.

"Silicone high-temperature resistant paint is composed of silicone resin, special temperature-resistant corrosion-resistant pigments, additives, organic solvents, etc. It is used for high-temperature anti-corrosion on the outer walls of blast furnaces and hot blast furnaces. It can also be used for chimneys, flues, exhaust pipes, high-temperature Hot gas pipes, heating furnaces, heat exchangers and other metal surfaces require high temperature corrosion protection."

Service phone number: 7x24 hours:400-878-0506